Farnborough: Airbus delivers first future wing demonstrator

Airbus has successfully delivered its first full-size wing prototype or ‘demonstrator’ through its Wing of Tomorrow programme to help mature next-generation wing technologies.

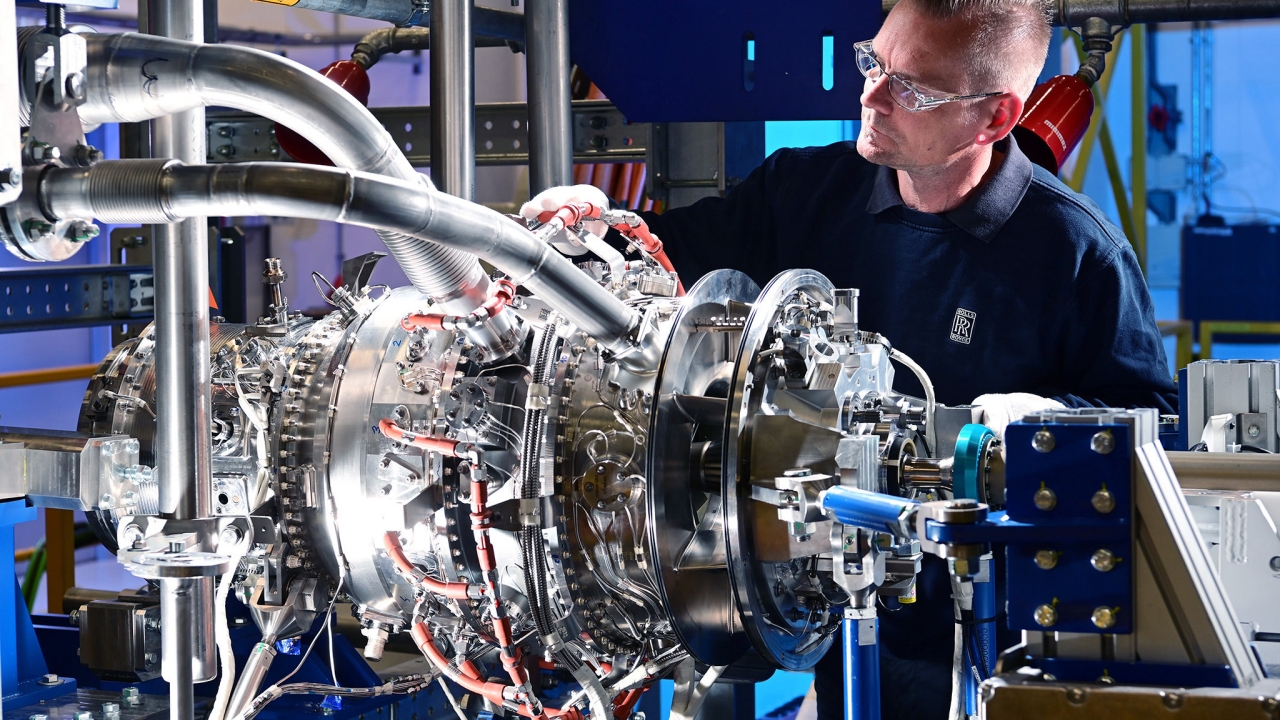

Airbus future wing demonstrator is delivered (Image Airbus)

The completion of the first of three fully composite wing demonstrators marks the integration of more than 100 different component and manufacturing technologies that include an all-new industrial assembly system, and which have helped validate key automation targets.

Speaking at the Farnborough Airshow, Sabine Klauke, Airbus chief technical officer, said: “Wing of Tomorrow brings a completely different build philosophy to the way we currently assemble wings and is a crucial part of our R&T portfolio that will help us assess the industrial feasibility of wing production in the future.”

The international team behind this UK-led programme is developing high-performing wing technologies, including the incorporation of a folding wing tip. Alongside research into sustainable aviation fuels and hydrogen propulsion, Wing of Tomorrow shows how Airbus is contributing to aviation’s decarbonisation ambitions and demonstrates the importance of large-scale industry collaboration in achieving our sector’s agenda for a more sustainable future.

The new build philosophy on Wing of Tomorrow eradicates in-tank working and enables manual and automated assembly to be smoothly integrated into an optimised industrial system. Through capturing the learning from building this first, and subsequent, wing demonstrators, Airbus will explore different scenarios to be able to make the right industrial choices to build our wings of the future.

Wing of Tomorrow composite components are designed to make the best use of technologies and reduce the amount of work during the assembly phase by more than 50%. Automation of the remaining drilling, achieving good tolerance control and wing shape, as well as the introduction of new approaches to inspection and validation will support Airbus’ ambition to create the most highly efficient wings of the future.

Stay up to date

Subscribe to the free Times Aerospace newsletter and receive the latest content every week. We'll never share your email address.